Каталог

Измерения геометрии и топологии

Настольные и напольные отрезные станки ручного и автоматического типа

Контрольное и измерительное оборудование для электронной промышленности, обеспечивающее разнообразные технологические нормы, объемы производства и типы изделий электронной техники.

Мы предлагаем оборудование для всех стадий производства электронных компонентов: от контроля чистых пластин и их обработки, до корпусирования и электрического тестирования готовых изделий.

Голографические микроскопы и профилометры

Голографические микроскопы и профилометры

Предназначены для высокоточного определения геометрических параметров пластин из полупроводниковых и диэлектрических материалов, выявления царапин, изгибов, деформации и других дефектов.

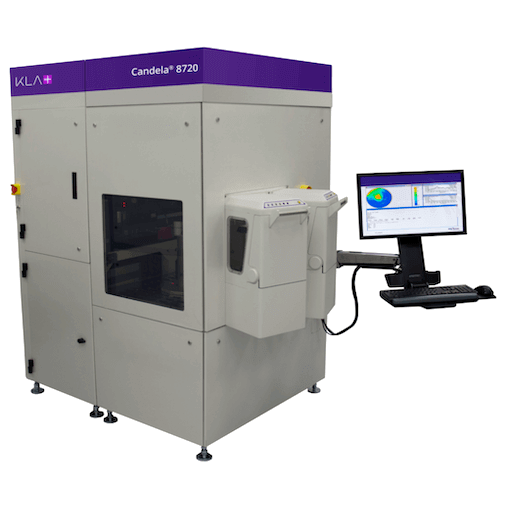

Установки измерения дефектности пластин

Установки измерения дефектности пластин

Позволяют оценивать качество пластин и подложек, применяемых для производства электронных компонентов, определять источник появления загрязнений, повреждений и структурных дефектов.

Виброизоляционные столы

Виброизоляционные столы

Антивибрационные платформы и системы изоляции для обеспечения минимальных помех при работе высокоточного оборудования.

Бренды оборудования

Сервис и ремонт измерительного оборудования

Выезд сервис-инженера

В кратчайшие сроки к вам приедет наш сервисный инженер для проведения ремонта.

Сервисный договор

Обслуживание «под ключ»: график выездов, экстренные выезды,склад запчастей «быстрого реагирования».

Диагностика и ремонт

Ремонтируем аналитическое и лабораторное оборудование всех ведущих марок, как представляемых эксклюзивно нами, так и сторонних производителей.

Гарантия и качество

Большой опыт оказания услуг по сервисному обслуживанию и ремонту измерительного оборудования.

ФОРМА ДЛЯ

ОБРАТНОЙ СВЯЗИ

Нажимая на кнопку "Отправить", я даю согласие на обработку персональных данных.

Напишите свой вопрос, укажите интересующее оборудование.

Наша почта

sales@imc-systems.ru

Наш телефон

+7 (495) 374-04-01