Оборудование для испытания различных материалов от биологических тканей до современных высокопрочных сплавов на сжатие, циклическое нагружение, усталостную прочность, ударные, многоосевые, реологические воздействия, растяжение и кручение.

Электромеханические испытательные машины

Электромеханические испытательные машины

Электромеханические испытательные машины совмещают в себе высокую эффективность использования пространства в лаборатории, простоту в работе и обслуживании с высокой точностью и широким диапазоном нагрузок.

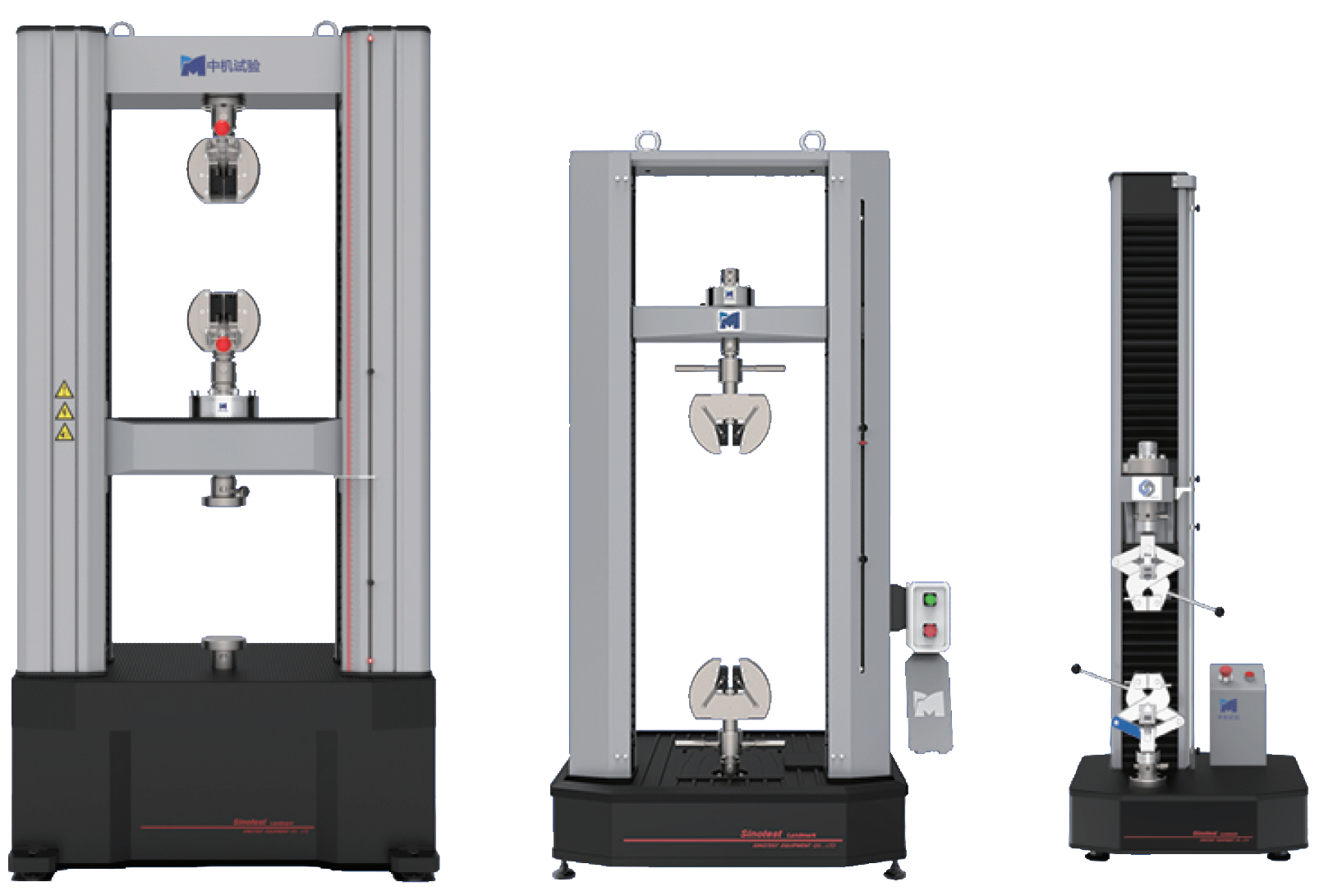

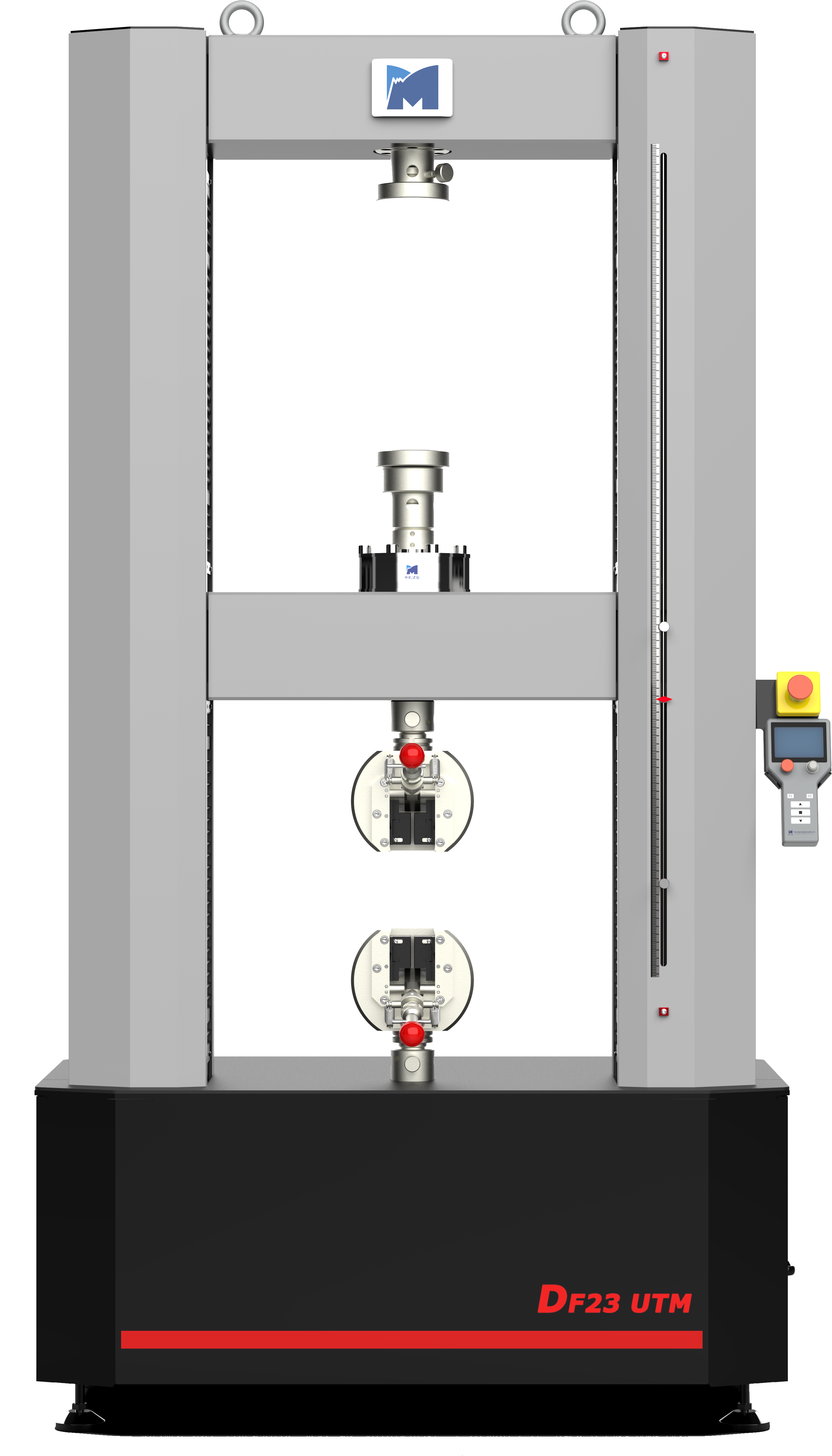

Гидравлические испытательные машины

Гидравлические испытательные машины

Предлагаем широкий спектр универсальных испытательных машин для больших рабочих нагрузок. Благодаря применению в рамах гидравлики, данные системы экономически выгодно использовать для нагружения в испытаниях на растяжение, сжатие, изгиб и сдвиг.

Динамические и усталостные машины

Динамические и усталостные машины

Динамические и усталостные испытательные машины предназначены для проведения испытаний под воздействием циклически изменяющейся нагрузки. Они идеально подходят для изучения механики разрушения материалов: многоцикловой и малоцикловой усталости.

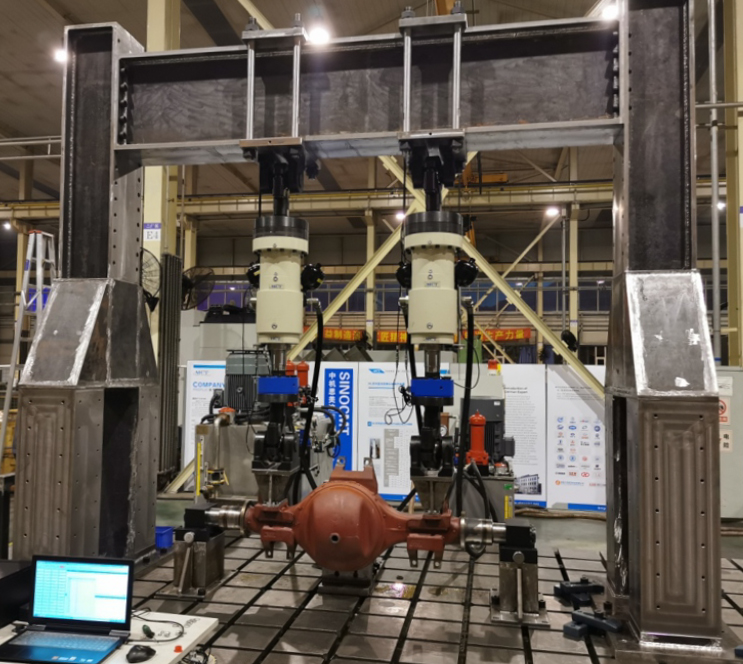

Гидравлические испытательные стенды

Гидравлические испытательные стенды

Заказные гидравлические стенды для испытаний материалов и правки деталей и компоненты к ним от производителя

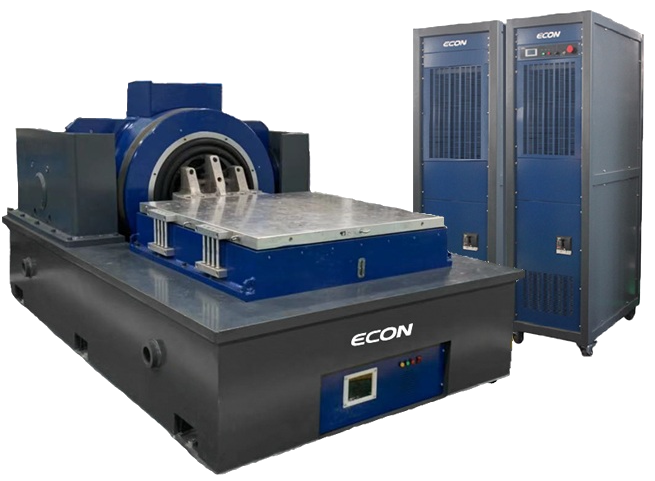

Вибрационные испытательные стенды

Вибрационные испытательные стенды

Позволяют проводить оценку параметров продукции при проектировании, апробации, упаковке и транспортировке, параметров надежности, испытания на усталость и моделировать различные условия влияния окружающей среды.

Наноинденторы и скретч-тестеры

Наноинденторы и скретч-тестеры

Исследовательские системы для анализа материалов, тонкопленочных и микро/ нанодисперсных систем

Механическая подготовка проб

Механическая подготовка проб

Широкий спектр решений для пробоподготовки: отрезные станки, оборудование для запрессовки и заливки, шлифовальное и полировальное оборудование, инструменты для петрографии, твердомеры по Виккерсу, Кнуппу, Роквеллу или Бринеллю и многое другое.

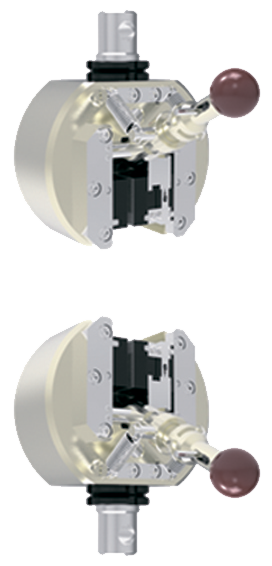

Приспособления для испытаний

Приспособления для испытаний

Захваты, экстензометры, приспособления для испытаний, все необходимое для организации процесса испытаний и измерений.

Бренды оборудования

Сервис и ремонт измерительного оборудования

Выезд сервис-инженера

В кратчайшие сроки к вам приедет наш сервисный инженер для проведения ремонта.

Сервисный договор

Обслуживание «под ключ»: график выездов, экстренные выезды,склад запчастей «быстрого реагирования».

Диагностика и ремонт

Ремонтируем аналитическое и лабораторное оборудование всех ведущих марок, как представляемых эксклюзивно нами, так и сторонних производителей.

Гарантия и качество

Большой опыт оказания услуг по сервисному обслуживанию и ремонту измерительного оборудования.

ФОРМА ДЛЯ

ОБРАТНОЙ СВЯЗИ

Нажимая на кнопку "Отправить", я даю согласие на обработку персональных данных.

Напишите свой вопрос, укажите интересующее оборудование.

Наша почта

sales@imc-systems.ru

Наш телефон

+7 (495) 374-04-01